Automatic dosing device

FROM: YIHUA DATE: 2021-07-30 Read()

Structure introduction

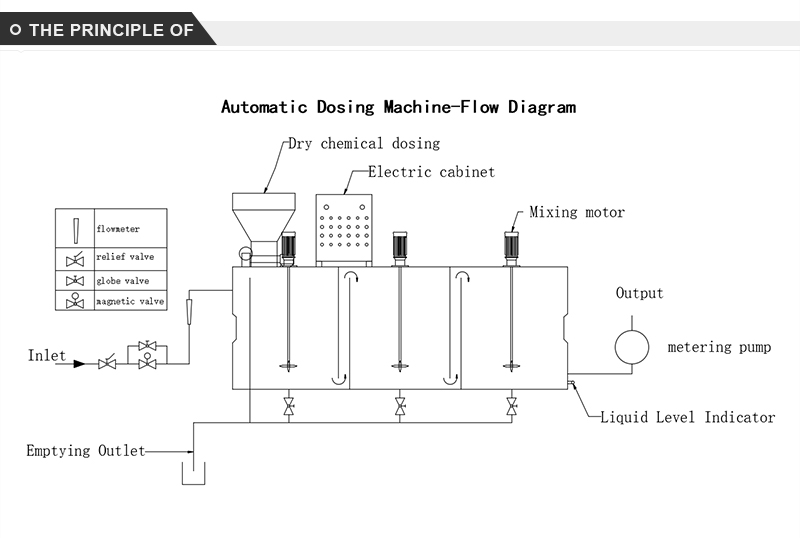

Water supply system

It is composed of inlet solenoid valve, flow meter and pressure reducing valve to ensure smooth water supply and no large fluctuation of pressure, and calculate and display inlet flow.

Dry powder feeding system

It is composed of screw pump, vibrator, heater and material level switch. The speed of screw pump is controlled by PLC and frequency converter, and dry powder is added according to the set concentration. The vibrator and heater can prevent the powder from becoming damp and caking

And the occurrence of metamorphism.

Dry powder premix system

Mixing tank, mixing tank, storage tank three tank in one, continuous processing. The ultrasonic level sensor detects the liquid level height, and the start and stop of the powder feeding motor and dosing motor are controlled by PLC.

Dosing system

Open and prepare two dosing pumps, controlled by frequency converter, set the motor frequency according to the actual dosing volume requirements, and control the dosage size.

The dosing pump selection must be made in the manual state, and the selection is invalid when the dosing pump is running.

Secondary dilution system

The inlet flow rate is manually adjusted by the pressure reducing valve. The inlet flow rate is displayed by the plate flowmeter, and the secondary dilution is carried out according to the concentration and dosage of the liquid. Install pressure reducing valve to ensure smooth water supply and no large fluctuation of pressure.

Automatic dosing device mainly including solution tank, mixer, metering pump, Y-type filter, safety valve, back pressure valve, check valve, pulse damper, water level gauge, pressure gauge, control cabinet, installation platform, etc. Installed on a base. The user only needs to place the combined dosing device in the dosing room, connect the dosing tube to the power supply, and start the operation. During the operation, the pH of the fluid is automatically detected and the corresponding liquid is added. A complete set of factory equipment can greatly reduce the workload of design and on-site construction, basically realize unattended, and provide a reliable guarantee for the quality, safety and on-site operation of the whole machine.

Automatic dosing device Features:

1. The equipment adopts corrosion-resistant materials with long service life and stable performance.

2. Automated control, the equipment can run automatically when starting up, dosing the medicine quantitatively, and automatically stop when the liquid level is low to avoid invalid operation of the equipment.

3. Highly integrated, saving space.

Automatic dosing device Applications:

1. Dosing of chemical agents under acid and alkali conditions.

2. Adding chemicals in sewage treatment projects

3. Quantitative dosing of chemicals in the chemical industry