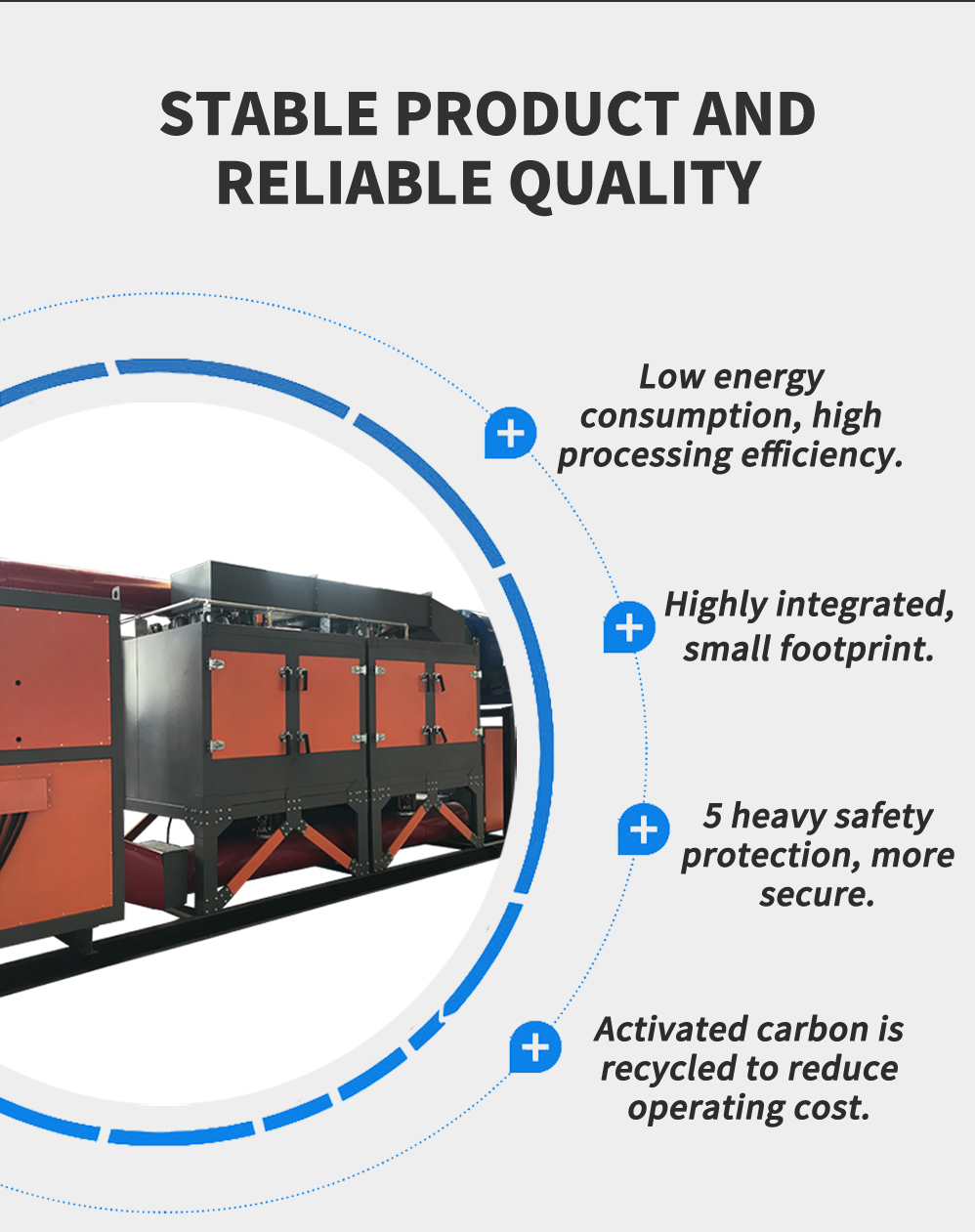

Catalytic combustion plant

FROM: YIHUA DATE: 2021-07-30 Read()

.

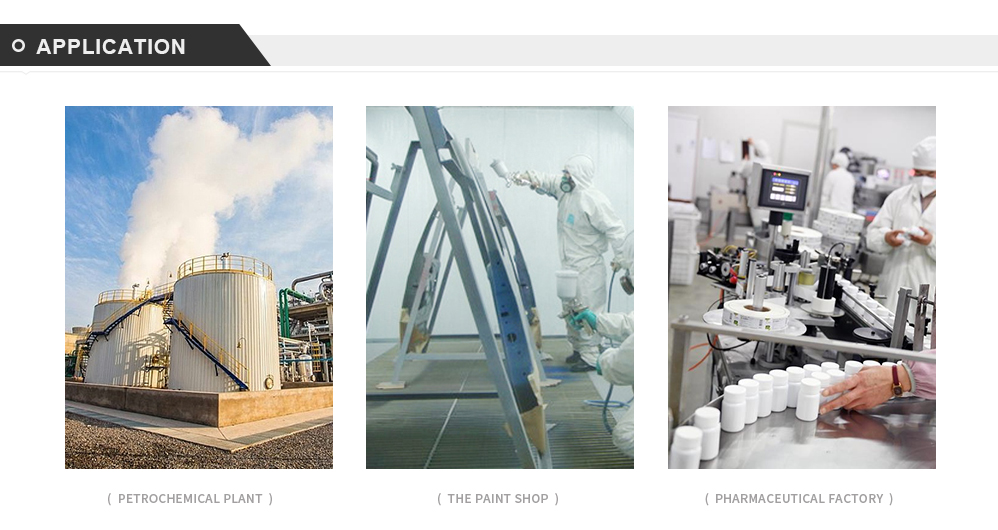

Suitable for petrochemical plant, chemical factory, pharmaceutical factory, cigarette factory, flavor factory, painting workshop, the use of waste gas types: alkanes, olefin, alcohol, ketones, ethers, esters, aromatic hydrocarbons, benzene and other hydrocarbon waste gas industry waste gas purification treatment.

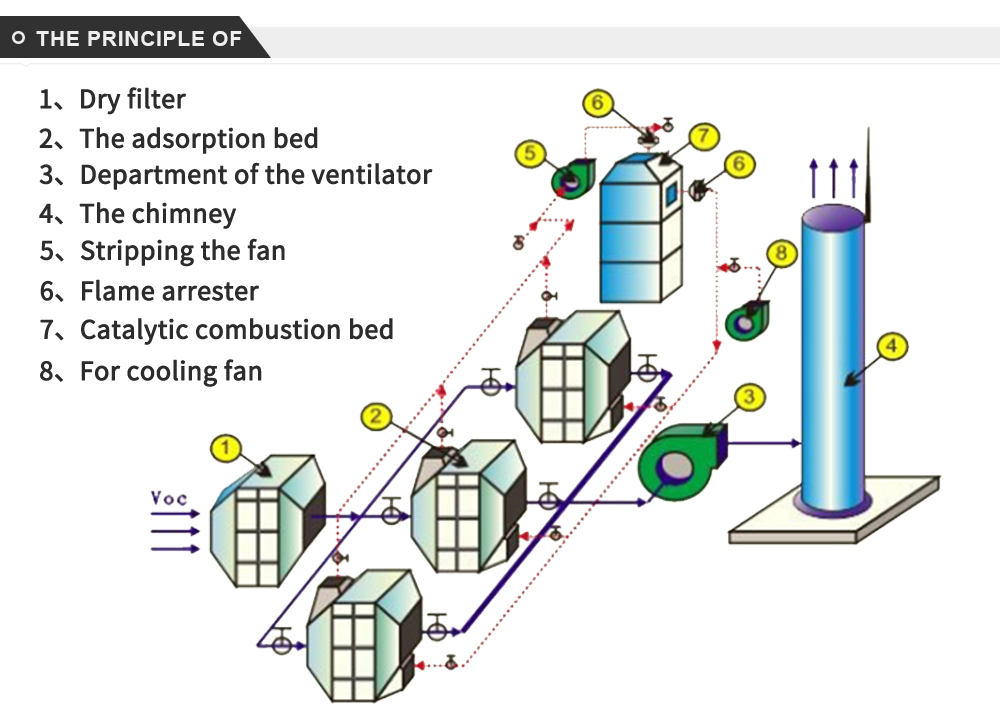

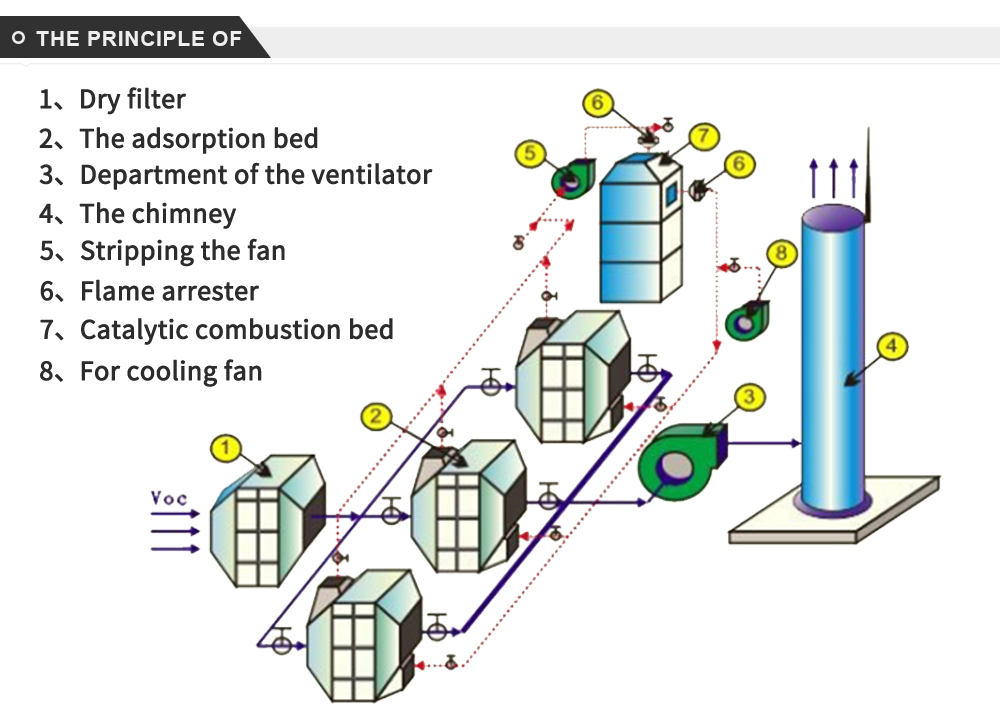

(1) activated carbon adsorption process:

The exhaust gas from the painting room enters the activated carbon adsorption bed through the pipe. When the organic exhaust gas passes through the activated carbon, the organic components in the exhaust gas are attracted to the micropores of the activated carbon and concentrated to be retained. The other gases pass through the activated carbon and are emptied by the fan.

(2) activated carbon desorption process:

Activated carbon used for a period of time, after adsorption of a certain amount of waste gas, will reduce or lose the adsorption capacity, at this time the activated carbon needs to be desorbed, desorbed activated carbon to restore the adsorption function can continue to be used. Stripping, activates the catalytic combustion preheating chamber, air preheating, preheating is into the adsorption gas box, box after activated carbon is heated, activated carbon adsorption gas evaporates, solvent by the fan into the catalytic combustor burning, burning decomposition generated CO2 and H2O after steam and hot air, hot air part back to continue to heat activated carbon, activated carbon adsorption box 叧 Part of the hot air is emptied and the activated carbon can be desorbed after repeated circulation inside the hot air.

Suitable for petrochemical plant, chemical factory, pharmaceutical factory, cigarette factory, flavor factory, painting workshop, the use of waste gas types: alkanes, olefin, alcohol, ketones, ethers, esters, aromatic hydrocarbons, benzene and other hydrocarbon waste gas industry waste gas purification treatment.